Composite nonwovens from pulp and carded webs

The WLS process already covers a wide range of nonwoven products, as the wet-in-wet process is able to process every fiber that is dispersible in water.

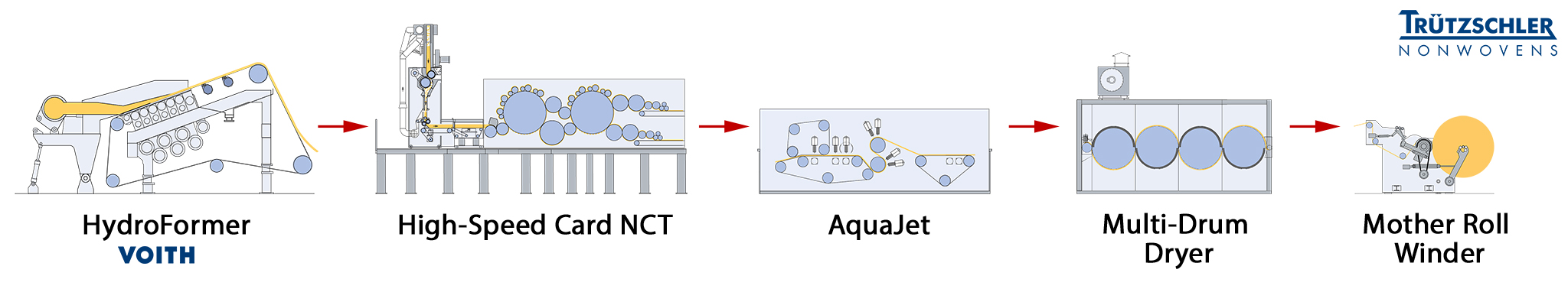

The integration of a TWF-NCT high-speed card in front of the AquaJet, i.e. before bonding, also allows for the production of CP (carded / pulp) nonwovens. These composite materials, each consisting of one layer of wet-laid and carded webs, can be designed to meet any requirements.

Line characteristics:

Typical web weights: 30 to 100 gsm

Fibers: wood pulp, viscose-/lyocell fibers, PET and other short-cut fiberss

Output: more than 20,000 tons/year

(depending on fiber type, web weight and working width)

Typical end products: high quality wet baby and body wipes, flushable wipes (MTT - moist toilet tissue)

Highest product variety

The flexible web forming concept including a HydroFormer made by Voith and the innovative carding technology from Trützschler Nonwovens, a wide variety of high-quality nonwovens can be produced on the production line installed. The spectrum ranges from carded nonwovens to wet-laid/spunlaced WLS materials to multi-layer CP products.