Targeting the production of isotropic nonwovens

Isotropic nonwovens have approximately the same strength in machine and cross directions. This MD/CD ratio of almost 1:1 makes it easier for converters to further process the nonwoven. Consumers favour the better look and the overall higher tear resistance.

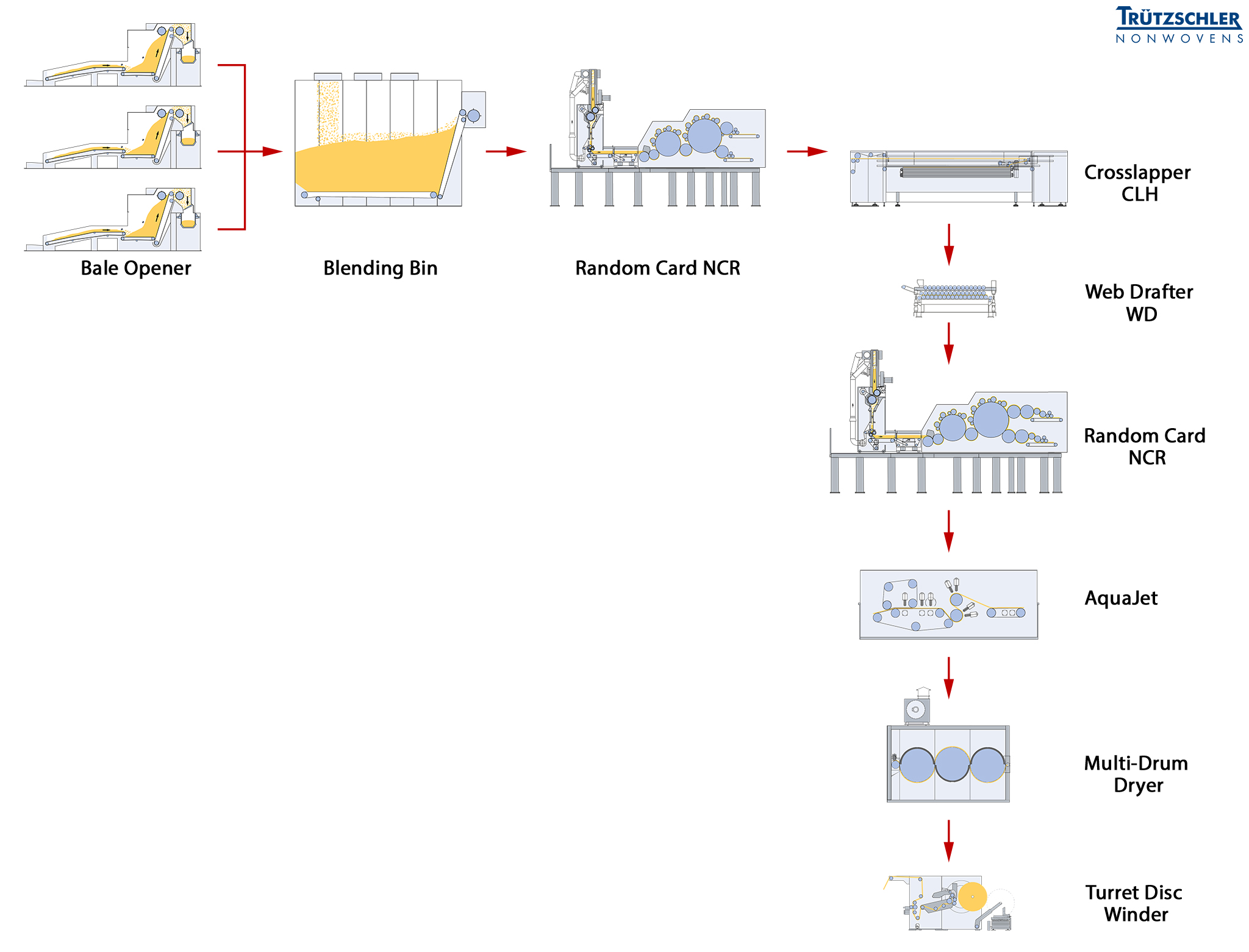

A production for isotropic, hydroentangled nonwovens always contains a crosslapper. Possible configurations are:

- Card – cross lapper

- Card – cross lapper - web drafter

- Card – cross lapper - web drafter - card

Line parameters:

Typical web weights: 30 to 400 gsm

Fibers: natural and man-made fibers

Output: some 7,500 tons/year

(depending on fiber type, web weight and working width)

Typical end products: beauty masks, high-quality wipes, coating substrates, technical nonwovens

The combination of crosslapper and web drafter

Precise layering by the crosslapper slows down the entire line significantly. However, the loss of speed can be partially compensated with a subsequent web drafter.