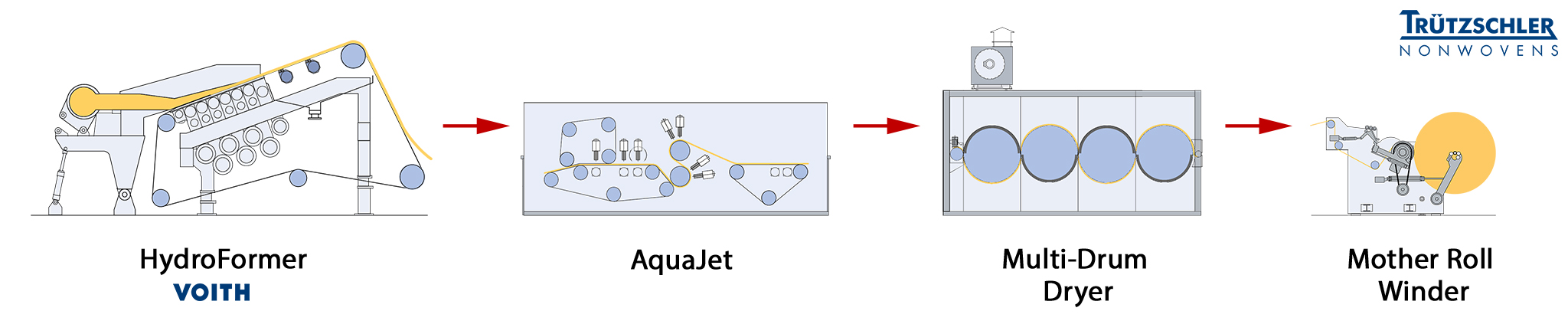

Lines for wet-laid, pulp-based nonwovens

Since 2013 Truetzschler Nonwovens and Voith have been offering complete lines for wet-laid and spunlaced nonwovens in close cooperation. The WLS technology (wet-laid / spunlaced), which has been developed to industrial market maturity, is able to process all fibers that are dispersible in water. WLS nonwovens correspondingly are highly versatile.

Line characteristics:

Typical web weights: 30 to 100 gsm

Fibers: wood pulp, viscose-/lyocell fibers, PET and other short-cut fiberss

Output: more than 20,000 tons/year

(depending on fiber type, web weight and working width)

Typical end products: high quality wet baby and body wipes, flushable wipes (MTT - moist toilet tissue)

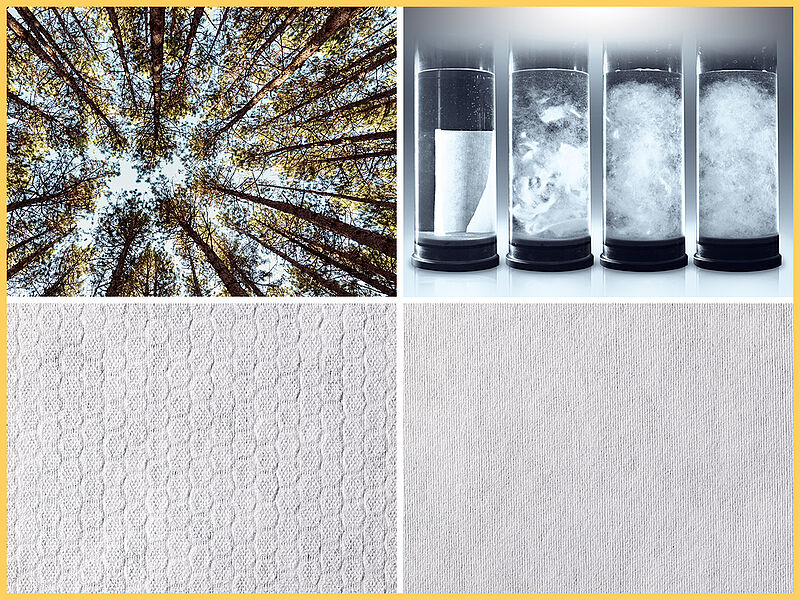

Sustainable nonwovens

The raw material for WLS nonwovens is largely inexpensive NBSK wood pulp, which is also used in paper production. With the addition of lyocell or viscose fibers, the wet-laying and spunlacing process creates environmentally friendly disposable products. Mechanical bonding with the help of high pressure water jets results in 100% biodegradable products from renewable resources.